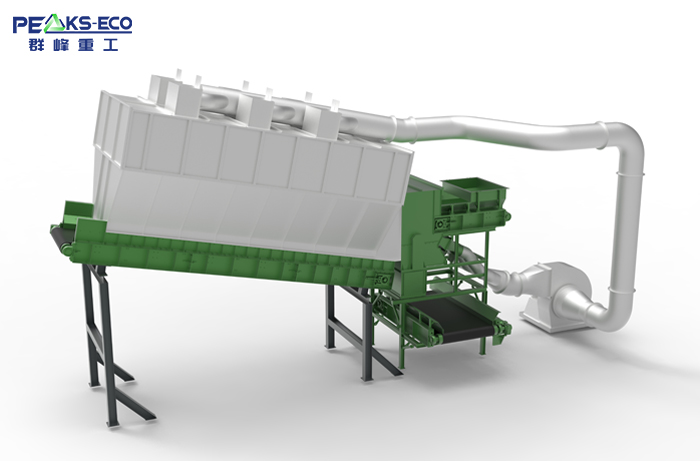

The air separation system uses air and wind to blow the waste stream, and then separates the waste according to gravity.

A waste stream is conveyed to the separator by a conveyor and heavy wastes with solid shapes (e.g. glass bottles and plastics) are dropped directly to the bottom of the separator. Glass bottles fall first, followed by plastic bottles, and then light wastes such as film and paper are blown away from the air flow of the blower and fall onto the end conveyor for separation. The dust is collected by the cyclone and the air circulates through the separator.

The system sorts the waste according to gravity and wind

The air separation system uses air and wind to blow the waste stream, and then separates the waste according to gravity.

A waste stream is conveyed to the separator by a conveyor and heavy wastes with solid shapes (e.g. glass bottles and plastics) are dropped directly to the bottom of the separator. Glass bottles fall first, followed by plastic bottles, and then light wastes such as film and paper are blown away from the air flow of the blower and fall onto the end conveyor for separation. The dust is collected by the cyclone and the air circulates through the separator.

The injection pressure and blower air volume are adjustable to optimize the separation efficiency and purity for glass bottles, plastics, cans, films and paper, depending on the purpose of separation. Cyclone separation process can absorb and purify polluted air, improve the working environment, reduce air pollution.

Air separators are usually installed in front of MRF (waste recovery plant) or MBT (bio-mechanical treatment) automatic sorters to sort film, paper and dust to achieve the efficiency and purity of automatic sorters.

Advantages:

Separation of materials at various gravity air rates

Efficient separation of heavy Waste (glass bottles)

Improve working environment through cyclone dust removal and air circulation

A good cyclone system can effectively screen film, plastic, paper and dust