With the continuous progress of urbanization, the number of waste wires and cables is increasing. These waste wires and cables not only occupy a large amount of land resources, but also cause serious harm to the environment and human health if not handled properly. Therefore, waste wire and cable recycling has become an important environmental issue. In this paper, we will discuss the significance of waste wire and cable recycling, the current situation, treatment methods and future development direction.

Recycling of waste wires and cables has multiple significance. Firstly, recycling waste wire and cable can reduce the demand for raw materials, thus reducing production costs. Secondly, waste wire and cable contains a large number of copper, aluminum and other valuable metals, through recycling can effectively achieve the reuse of resources. In addition, waste wire and cable may also contain some rare metals and precious metals, the recycling of these metals is important for the protection of resources and promote the development of circular economy. Finally, recycling waste wire and cable can also reduce pollution to the environment and protect the ecological balance.

At present, the recycling of waste wires and cables has been widely concerned and emphasized. The governments of many countries and regions have introduced relevant laws and regulations, requiring enterprises and individuals to recycle used wires and cables. At the same time, many enterprises have spontaneously carried out the business of waste wire and cable recycling, and effectively processed and reused the waste wire and cable through scientific methods and technologies.

However, there are still some problems and difficulties in the recycling process due to the large number and variety of waste wires and cables, and the difficulty in processing. Among them, the most important problems are how to improve the recycling efficiency and resource utilization rate, how to reduce the treatment cost and improve the environmental performance, etc.

Treatment of waste wire and cable requires the use of scientific methods and technologies. At present, the common treatment methods mainly include mechanical treatment, chemical treatment and so on. The specific choice of treatment method needs to be based on the actual situation for comprehensive consideration, including the type of waste wire and cable, quantity, value, environmental requirements and treatment costs and other factors.

1. Mechanical treatment

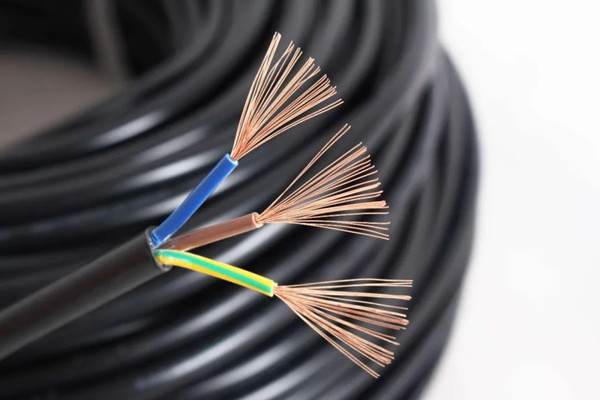

Mechanical treatment is a common method of waste wire and cable treatment. This method mainly involves separating and recycling different components of waste wire and cable by physical means, such as crushing and sorting. Mechanical treatment has the advantages of low cost, high efficiency, etc., but at the same time there are problems such as low resource utilization rate and limited metal recovery rate.

2. Chemical treatment

Chemical treatment is another common method of waste wire and cable treatment. The method is mainly through the chemical reaction, the metal elements in the waste wire and cable will be extracted. Chemical treatment has the advantages of high metal recovery rate and low treatment cost, but it also has the problems of high environmental pollution and high consumption of chemical reagents.

Peaks-eco is developing a sustainable recycling solution aimed at recovering production waste cables. As technology advances and equipment is replaced, large quantities of used cables are created as a result. These cables, which are mainly made up of metal conductors, plastic jackets and packaging materials, are not only a waste of space, but also potentially polluting to the environment if they are piled up directly at a disposal site. However, these waste cables contain a lot of valuable substances, such as copper, aluminum, plastic, etc., which can be transformed into renewable resources through recycling.

Advantage:

Compact & Environmentally Friendly

- Complete set of cable recycling lines in containers.

- Significantly reduce dust emissions with an industrial-grade dust removal system;.

- Intuitive, integrated monitoring system.

Plug & Play

- User-friendly, just plug and play.

- No assembly required, eliminating time spent training operators.

Minimum size - maximum efficiency

- Feeding via crane, belt conveyor or forklift.

- Heavy-duty machinery from Qunfeng Heavy Industries.

- Pelletizing and sorting power and reliability.

- Designed to handle large quantities of material, up to 0.5 to 2 tons per hour of sorting capacity, which may vary depending on the quality of the material.

- Output products: ferrous metals, non-ferrous metals and plastics.

- Automatic feeder with visual control and leveling sensors.

With the increasing awareness of environmental protection and the continuous progress of technology, the future development direction of waste wire and cable recycling will pay more attention to environmental protection and resource recycling. Specifically, the following aspects will become the focus of future development:

1. Explore more efficient recycling and treatment technology: continue to increase scientific and technological research and development efforts to explore more efficient waste wire and cable recycling and treatment technology to improve resource utilization and metal recovery rate.

2. Develop environmentally friendly treatment methods: focus on environmental performance, develop environmentally friendly treatment methods for waste wire and cable to reduce pollution and damage to the environment.