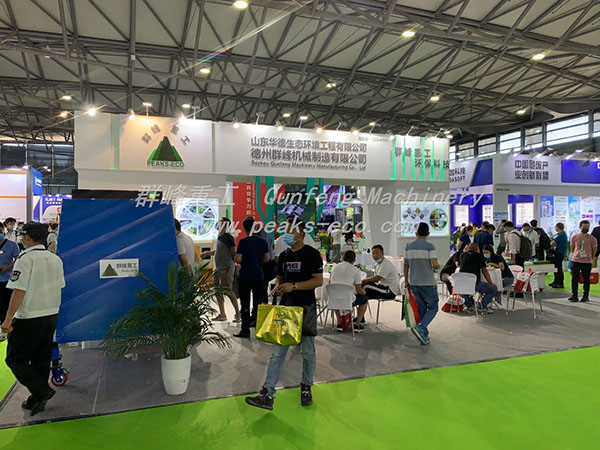

The 21st China Environment Expo 2020

Time: August 13-15, 2020

Venue: Shanghai New International Expo Center

The 21st China World Expo, co-sponsored by the Munich Expo Group, the Chinese Society of Environmental Sciences, the Environmental Chamber of Commerce of the All-China Federation of Industry and Commerce, and China Trade Munich Exhibition (Shanghai) Co., Ltd., has been held on August 13-15, 2020 Successfully held in Shanghai New International Expo Center. 1,851 exhibitors showcased their innovative technologies and solutions in the fields of water, solid waste, air, soil, and noise pollution. The 3-day exhibition attracted 73,176 professional visitors. During the exhibition, more than 400 unique conferences and concurrent activities were held, covering a wide range of topics and hitting a record high.

In order to meet the exhibition needs of environmental protection companies, the 22nd China Environmental Expo IE expo 2021 will be expanded to a display scale of 160,000 square meters, focusing on the world's leading sewage treatment, Excellent enterprises, cutting-edge technologies, and high-quality solutions in the field of environmental pollution control such as pumping pipe valves, solid waste treatment, resource recycling, air pollution control, site restoration, environmental monitoring, environmental service industry, etc.

The 2021 China Environmental Technology Conference and Summit Forum will also be held during the same period. From the Ministry of Ecology and Environment, Ministry of Housing and Urban-Rural Development, National Development and Reform Commission, Ministry of Water Resources and other policy-making departments, Chinese Academy of Sciences, Chinese Academy of Environmental Sciences, Research institutes such as Tongji University and Tsinghua University, European Water Association, World Water Environment Alliance, German Water, Sewage and Waste Treatment Association, , International Solid Waste Association, German Municipal Sanitation Vehicle and Equipment Industry Association and other international authoritative organizations, and more than 100 industry-leading experts from leading technology companies participated in more than 400 professional conferences and forums throughout the process, committed to creating a one-stop environmental technology exchange platform for politics, industry, education, and research.

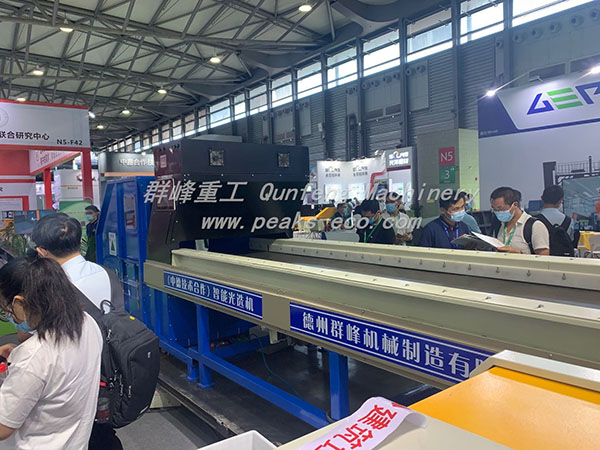

The exhibition attracted many domestic and foreign experts and exhibitors. As an exhibitor, our company brought waste treatment equipment and the latest intelligent optical sorter equipment, as well as our waste sorting process model to the exhibition, mainly for domestic waste, garden waste, kitchen waste, construction waste.

1. Working principle

Near-infrared light with wavelengths from 1100 nn to 1900 nn will have significantly different absorption and oscillation effects for different compositions such as common chemical bonds in plastic raw materials. The reflected light of different materials can form a unique spectrum. The spectrometer camera designed with this feature is particularly suitable for analyzing and identifying different plastic components.

2. Features

1) Fast sorting speed: 500 times per second scanning frequency and "Free Fall" design, the sorting detection position is close to the valve port, avoiding the time error of the blow-off action, greatly increasing the accuracy, and avoiding Various misjudgments caused by surface pollution and related cleaning problems.

2) Unique light source: The uniquely designed focusing halogen lamp can achieve the requirements of maximizing brightness and minimizing energy consumption. Easy-to-exchange design reduces maintenance costs.

3), modular valve seat: modular valve seat design, can meet the needs of different materials, replace different apertures. The valve seat is designed to be replaceable, which can be matched with different sizes of material sources and belt widths. The blowing time control at the millisecond-level greatly reduces air consumption.

4) Integrated interface: Systematic design with two independent operation touch screens, all actions and messages are clearly presented.

5) Safe and reliable: the highest specification safety components and circuit system design are adopted to ensure the safety of operation and comply with relevant safety regulations.

3. Workflow

1) Feeding: the screw or conveyor belt feeds the material and transports it to the vibration dispersion machine. The feeding speed is adjustable.

2) Vibrating sieve dispersion: Use dual vibration motors and screens to filter out too small particles, and the material will be evenly dispersed in the future and sent to the main conveyor.

3) Sorting

The main conveyor belt accelerates the raw materials. When the materials fly out, the infrared light above the exit will be absorbed by the materials and reflected the sorting host. After the host computer scans and analyzes and judges, the high-speed blowing valve blows the material to different receiving areas.

4) Receiving

The conveyor belt in the first zone will take out the materials that have not been blown away, and then will be guided into the receiving space bag by the two-way screw rod after being raised. The blown away material falls into the second zone conveyor belt, is led out and raised, and then introduced into another receiving space bag.