Qunfeng Heavy Industry has successfully won the Songyang County Solid Waste Resource Recycling Construction Waste Pretreatment Project by virtue of its breakthrough innovative construction waste resource utilization 3.0 technology. The project is the first multi-functional solid waste recycling complex project in China that organically integrates the disposal of construction waste, energy utilization of multi-source solid waste and synergistic solid waste disposal with ceramic granules.

The project is located in Songyang County, covering an area of 105 acres. After the completion of the project, the disposal end can realize the annual disposal of 400,000 tons of engineering sludge, sludge, polluted soil and other solid waste, demolition waste and renovation waste 150,000 tons of industrial solid waste, garden waste and waste biomass and other combustible solid waste 50,000 tons; product end to achieve the production of recycled aggregate 110,000 tons/year, 400,000 square meters of green ceramic granule building materials/year, the use of waste heat to supply heating 15t/h, photovoltaic capacity of 3.5MW, the disposal of solid waste to achieve the red line in the project. The solid waste disposed of in the project within the red line “eat dry clean”, the resource utilization rate of recycling is close to 100%.

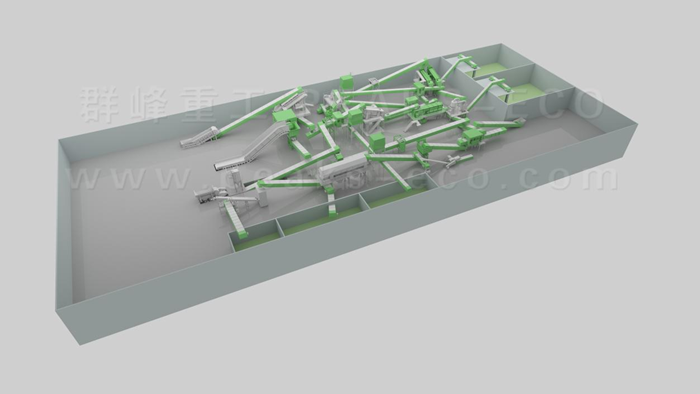

The project innovatively adopts the “three-in-one” process line integration design, the integrated process line simultaneously meets the production of demolition waste, decoration waste, combustible SRF and RDF. For the demolition and decoration waste, “three-stage screening + two-stage crushing + multiple wind selection” combined processing technology is adopted to fully sort the materials and ensure that the quality of the finished aggregates meets the requirements.

The highlight of this project is its excellent processing capacity, which covers: demolition waste with an annual disposal capacity of up to 100,000 tons, renovation waste with an annual disposal capacity of 50,000 tons, bulky waste with an annual processing capacity of 1,000 tons, garden waste with an annual processing capacity of 3,000 tons, general industrial solid waste (especially combustible) with an annual processing capacity of 10,000 tons, as well as mushroom sticks and other biomass waste with an annual processing capacity of 45,000 tons.

The two-stage crushing process for general industrial solid waste and mushroom rods emphasizes the flexibility of switching between different particle sizes to achieve the production of SRF combustibles and RDF fuel rods. As the industry's first case of integrating general industrial solid waste, biomass and construction and renovation waste, this project provides a new way of thinking about the treatment of demolition and renovation waste.

Songyang's construction waste treatment system is not only limited to the production of recycled aggregates from construction waste, but is also committed to the integrated treatment of biomass, general industrial solid waste and other types of waste, which are innovatively converted into SRF (Solid Recycled Fuel) and RDF (Refuse Derived Fuel) to provide green energy for the power station in the industrial park. In order to fully meet these diversified production needs, the project has achieved a major breakthrough in process line design, skillfully integrating a full set of production processes for demolition and renovation waste, bulky waste, general industrial solid waste and biomass waste treatment. Through the efficient time-sharing production strategy, the system is able to flexibly dispatch and maximize the use of shared equipment modules to accurately meet the demands of different production functions, demonstrating a high degree of flexibility and integrated innovation.

It is not only an efficient waste treatment system, but also a comprehensive example of resource recycling. By integrating the treatment processes for many types of waste, including demolition and renovation waste, bulky waste, garden waste, general industrial solid waste and biomass waste, this project successfully realizes the diversification and high efficiency of waste treatment. At the same time, the waste is converted into SRF and RDF fuels, which provide sustainable green energy for the power station in the industrial park, demonstrating the great potential of circular economy. This innovative treatment mode and efficient resource recycling method is an important demonstration and leading role in promoting the transformation and upgrading of the solid waste and garbage treatment industry and promoting sustainable development.