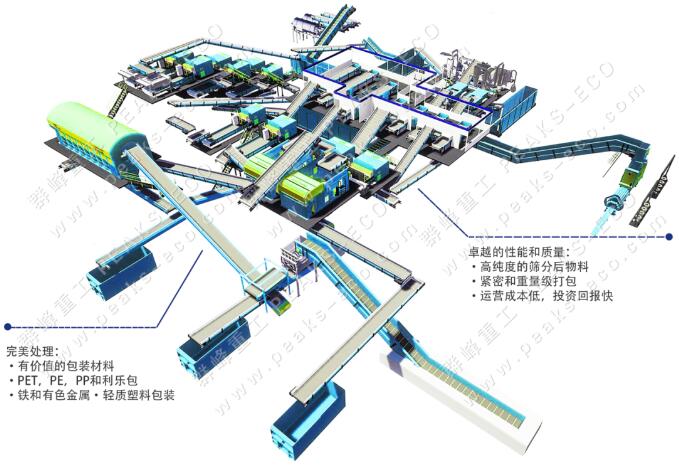

The process of plastic waste sorting and deep processing is divided into two parts: the first part is the material sorting line, and the second part is the plastic bottle washing and slicing line.

Mixed plastic raw materials first enter the integrated machine for unpacking and loading to be broken up and evenly fed to the subsequent sorting and processing facilities. After magnetic separation to remove magnetic metal, the material enters the pop-up sieve to get 2D material, 3D material and crumbs, 2D material and crumbs enter the cache bin for storage and spare, 3D material is processed by eddy current sorting, pre-cleaning machine, de-labeling machine, negative pressure air separator, disk sieve, to remove non-magnetic metal and sundry in the material, and remove the dirt label on the bottle body to facilitate the subsequent intelligent sorting of plastic bottles. After pre-treatment of plastic bottles into the light selection for detailed classification, the material is classified according to the material into transparent and light blue PET material plastic, mixed PET plastic and the final residue. Mixed PET plastics enter the baler to be baled into pieces, transparent and light blue PET materials enter the subsequent plastic cleaning and slicing processing line for deep processing, and the final residual material enters the cache warehouse for subsequent disposal.

The sorted and processed plastic bottles are firstly sorted manually and magnetically to remove the impurities in the materials, and then enter the crusher to crush and reduce the volume. After crushing, the plastic bottles enter the mechanical dryer, and while drying, the bottles are screened for impurities; after screening, the small-size materials are discharged into the cache bin; the large-size bottles enter the folded-plate wind and magnetic separator to further remove light substances such as plastic labels and magnetic metals; the bottles after the above treatment enter the cache bin for storage and the bottles will be subsequently processed by in-depth de-immersion and cleaning. Bottle materials in the cache bin into the rinsing tank for cleaning and flotation, and then into the horizontal washing machine for further cleaning, after rinsing and cleaning of bottle flakes into the hot washing machine to remove the glue material on the surface of the bottle flakes, and then through the magnetic drum, eddy current sorting, fine screening + wind selection and color sorter, in addition to impurities and fine points of PET bottle flakes of different colors.

Plastic Recycling Washing and Pelletizing System