Optical separator is a key equipment commonly used in the resource recycling industry. Light sorters have a wide range of applications in the resource recycling industry and are very promising. Its combination with artificial intelligence shows more powerful vitality. Driven by the trend of artificial intelligence, Qunfeng Heavy Industry's optical separator is more intelligent and develops more rapidly.

Artificial intelligence optical separator has come, are you ready?

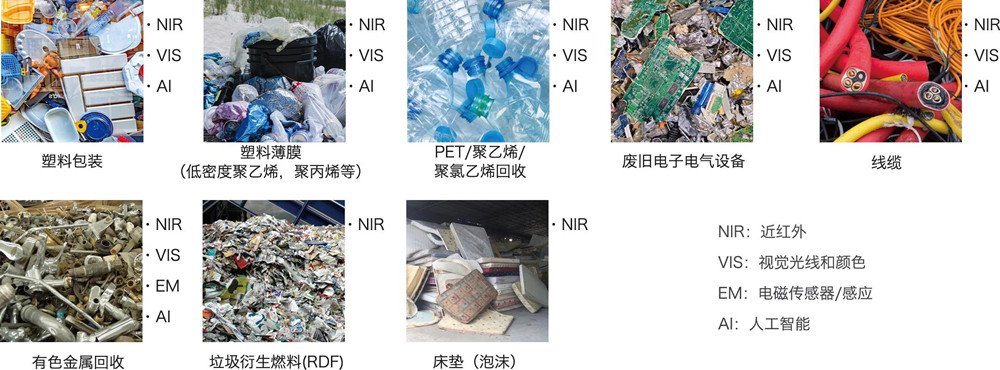

QUNFENG Heavy Industries NIR Light Sorting can automatically classify and separate various types of materials based on composition (NIR/MIR), color (visual light and color), inductive sensors (electromagnetic induction) and artificial intelligence (shape and appearance).

Thanks to the flexibility of multispectral vision, this multifunctional sorter can be configured to adjust its configuration to sort new materials that may appear in the feed stream.

The machine can be used on accelerated belts from 1000 mm to 3000 mm, with different separation options (double bar or multi-track) depending on the customer's needs.

Functions and features:

Brain “add-on”, artificial intelligence based on deep learning algorithms;

High productivity under demanding industrial conditions;

High recovery and purity of target materials;

online customer service for prompt remote assistance;

computer-aided calibration providing high reliability and stability;

real-time online access to classified material statistics (interface);

short payback cycle makes it a worthwhile investment;

easy to maintain with standard off-the-shelf spare parts;

versatility and flexibility in sorting different materials speedy remote assistance.

The Qunfeng Heavy Industries NIR Light Sorting is equipped with Near Infrared (NIR) spectroscopy for the identification of different polymers. NIR technology measures the wavelength and intensity of NIR light absorption.

The absorption reflectance spectrum is proportional to the chemical composition of the polymer. In other words, this device uses infrared light to obtain a chemical fingerprint of the polymer at a specific point in time.

NIR technology is characterized by fast, accurate, reliable, cost-effective and non-destructive measurements for identifying materials and colors. As a result, this device is a great investment with a guaranteed ROI.

For the detection and separation of mixed waste and other metals. When an electric current flows through the sensor, the sensor generates a magnetic field. This depends on the composition of the material.

Artificial Intelligence brings together different technologies from machine learning to natural language processing to enable machines to perceive, understand, act and learn. By combining Artificial Intelligence with machine vision, we are able to provide our systems with decision-making and response capabilities unheard of in the industry.

Optional Equipment

-Multi-track

-Automatic blow bar positioner

-Dual blow accuracy

-Valve self-test

-VPN network connection

-Extreme operating temperature control

-Use of medium wave to recognize black/black polymer