Commercial and industrial waste usually contains a mixture of wood, metal, plastic, cardboard, and paper, and may also contain small amounts of concrete, bricks, rubble, and soil.

With commercial and industrial waste processing systems, ferrous metals, non-ferrous metals, inert materials (e.g., bricks, concrete), and combustible materials are screened out of the material. The screened metals are transported to specialized outside companies for sorting and recycling. Inert materials are recycled into construction aggregates. Combustible materials are processed into engineered fuels (PEF), which can replace traditional fossil fuels.

The coarse crusher is specially designed for the crushing of large-volume or large-volume materials such as household garbage, bulky garbage, and vehicle shells. The material can be crushed to a particle size of 100-350MM.

Through the rotation of the disc and the gap between the discs, the garbage of different particle sizes and shapes are separated. By adjusting the gap between the discs, materials of different particle sizes can be effectively and reasonably separated.

The air separation system sorting technology utilizes the density characteristics of garbage and uses airflow to effectively sort the garbage. This technology can improve the recovery rate of small-volume garbage. The appearance and function of the equipment are individually designed to meet the different needs of customers.

The metal magnetic separation system uses magnets to separate the iron metal in the garbage without a motor drive. The conveyor belt rotates around a huge magnet to separate the steel wire, nails, and gas tank. The body of the magnetic separator is made of steel and is non-magnetic, so as to avoid attracting iron materials to the body of the magnetic separator.

Two screenings can be carried out in one operation, providing a highly efficient screening solution for handling viscous and moist materials. It is an ideal choice for processing compost, wood, garbage, trommel fines, construction waste, and incinerator ash.

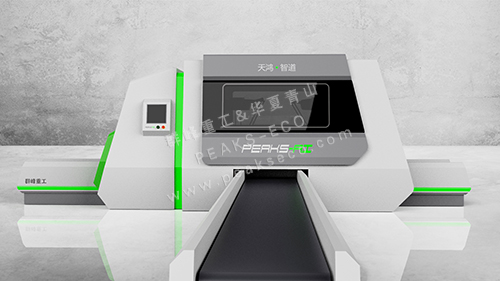

Adopting superior artificial intelligence technology to identify waste of different materials, in order to achieve accurate, active product recycling and precise quality control. Its sorting accuracy is as high as 90% and can work continuously for 24 hours * 7 days. Use the power of science and technology to promote the reduction, resource utilization, harmless and intelligent' disposal of garbage.

According to the difference of different sizes and shapes of materials, when moving on an inclined surface or colliding with the inclined surface, different movement speeds and bounce trajectories will be generated, and the materials will be separated. This equipment is often used for household waste sorting to separate sheet-shaped 2D materials from three-dimensional 3D materials.

Various types of equipment are available, which can co-process a variety of materials

Strong crushing ability, improve production efficiency

Greater load-bearing strength and higher stability

Qunfeng Heavy Industry owns a waste recycling system factory, please feel free to contact us if you need them.