With the rapid development of globalized production and consumption patterns, plastic products are widely used in various fields because of their lightweight, durable, low-cost and other advantages, but at the same time there is also a large amount of waste plastic waste. According to statistics, about one-third of the plastics produced globally each year are not effectively recycled, causing serious environmental pollution problems. Reasonable recovery and recycling of waste plastics is not only an urgent need to reduce the burden on the environment, but also an inevitable choice to achieve sustainable economic development. In this paper, we will discuss the importance of recycling waste plastics, the current challenges and the future path of innovation, aiming to provide reference for the construction of a circular economy system.

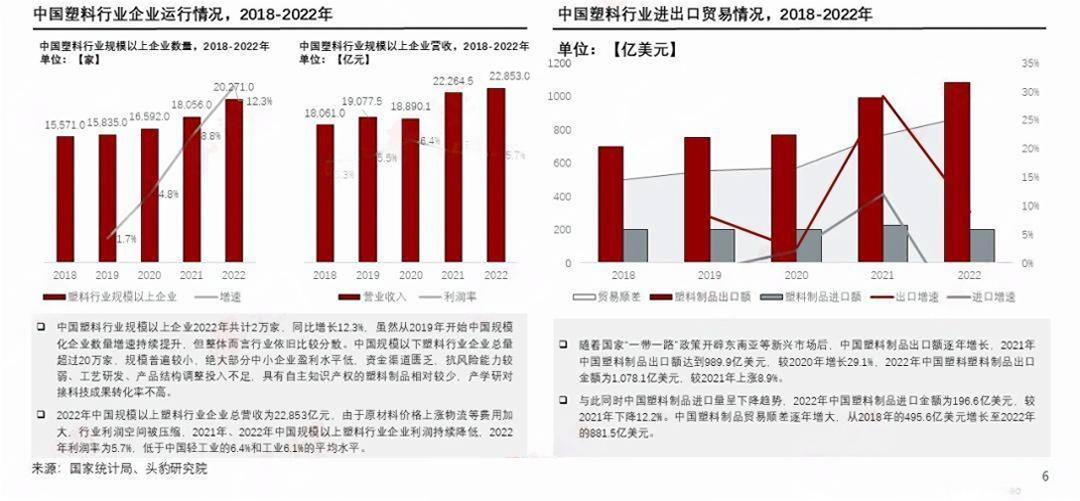

China's plastics industry as a whole the industry remains relatively decentralized, in 2022 China's plastics industry above-scale enterprises totaled 20,000; China's plastic products exports have been growing year by year, in 2022 China's plastic plastic products exports amounted to 107.81 billion U.S. dollars, an increase of 8.9% compared with 2021.

China's output of plastic products in 2019-2022 stays above and below 80 million tons, with plastic sheet, tube and pipe profiles, plastic wire rope and woven plastic products accounting for 64% of the total plastic output; China's recycling of waste plastics will be 18 million tons in 2022, a decrease of 5.5% from the previous year.

Recycling is the most economical and reasonable disposal method to solve the plastic pollution problem

China produces a large amount of waste plastic products every year, bringing huge environmental pressure to the whole society. According to the estimation, the proportion of plastic in solid waste is less than 10% (by mass), but because of its not easy to decompose and the volume of large and irregular, difficult to deal with the characteristics of the visual pollution, soil pollution, water pollution, climate change, and affect human health and many other problems.

The significance of reusing waste plastics:

Saving resources and reducing environmental pollution:

Plastic Resource Recycling saves energy and resources by recycling waste plastics, reducing dependence on virgin petroleum resources.

It reduces the generation of plastic garbage and reduces the pollution to the environment, such as the accumulation of plastic garbage and the pollution of plastic particles.

Reduces greenhouse gas emissions:

The production and disposal of plastics generates large amounts of greenhouse gases, such as carbon dioxide and methane. By recycling plastics, the demand for plastic production can be reduced, thus reducing greenhouse gas emissions.

Economic Benefits:

Recycling plastics creates jobs and promotes economic development.

By recycling plastics, the cost of raw materials can be reduced and the competitiveness of companies can be improved. Plastic recycling industry not only creates many employment opportunities, but also drives the development of related industries. Recycled plastics can be used in the production of recycled products, such as recycled plastic bags, fibers and construction materials. This not only reduces production costs, but also brings considerable economic benefits to enterprises.

Although the recycling of waste plastics has received more and more attention, it still faces a number of challenges in practice:

Difficulty in classification: There are many types of plastics, and the mixed collection of different types of plastics increases the difficulty of subsequent sorting and reduces the recycling efficiency.

Insufficient economy: the cost of recycling and processing waste plastics is relatively high, and the added value of recycled products is limited, lacking sufficient economic incentives to attract enterprises and individuals to actively participate.

Technical bottlenecks: Some existing recycling technologies, such as physical recycling and chemical recycling, still have certain technical limitations, making it difficult to meet high quality recycling standards, and some of the methods may produce secondary pollution.

Weak Public Awareness: Consumers do not know enough about the importance of recycling waste plastics, the habit of garbage classification has not been generally developed, and the participation in source reduction and recycling is not high.

Facing the above challenges, QUNFENG Heavy Industry actively explores and designs, builds and operates a full range of plastic resource utilization for recyclable garbage, especially plastic.

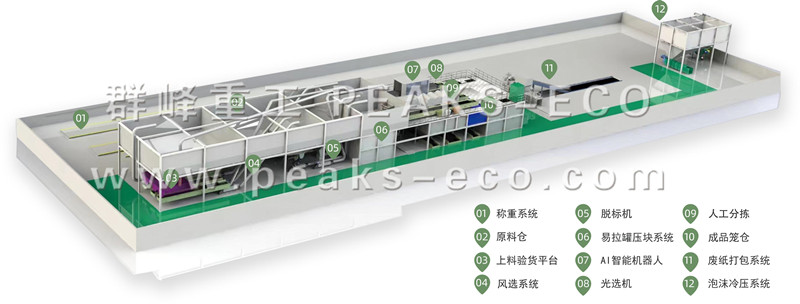

Fourth Generation Sorting Center - Adopting wind conveying and AI intelligent system

After the recyclable materials are transferred into the factory, plastic bottles and cans enter the house inspection platform, and according to the different material conditions, they are sent to different storage bins by the wind feed system. Monochrome bottles are transported to the de-labeled ones into the transit bin for temporary storage by the wind feed system, and then transported to the AI intelligent robots and light sorters by the wind feed system to be classified into PET, PP and PE, and then packaged. Other miscellaneous plastic bottles are transported to the manual sorting platform through the wind conveying system, classified into four different colors of plastic bottles: blue and white, Lehu, miscellaneous colors and green bottles, and then packaged.

This process is the best choice for separating plastic, metal and electronic wastes as well as contaminated and mixed plastic substances. QUNFENG Heavy Industry can provide tailor-made solutions for plastic resourcing projects, seeking a balance between customer-specific requirements and investment to meet the needs of the customer. The recyclable systems offered by QUNFENG Heavy Industry have low operation, maintenance and repair costs, achieving optimal resource utilization with minimum investment.

Excellent performance and quality:

-High purity post-screening material

-Compact and heavyweight baling

-Low operating costs and fast return on investment

Perfect processing:

-Valuable packaging materials

-PET, PE, PP and Tetra Paks

-Ferrous and non-ferrous metals -Lightweight plastic packaging

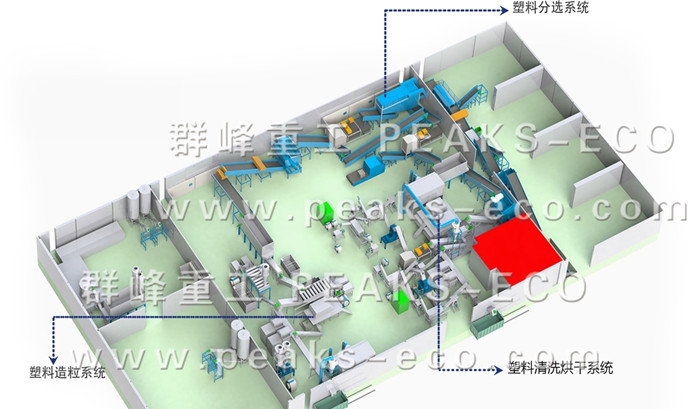

The collection and transportation system of QUNFENG Heavy Industry is regionalized and standardized according to “Point-Station-Center”. Qunfeng Intelligent Sorting Center will collect the recyclable materials for standardized process operation, realizing the classification of raw materials and district warehousing - pre-treatment intelligent sorting - intelligent classification and storage - renewable product manufacturing - the whole process of renewable resources and product sales one-stop landing. In the application of intelligent equipment, Qunfeng Heavy Industry will continue to improve the applicability, intelligence and automation level of each sorting and processing module.

3D effect diagram of plastic resource system