The slag produced by garbage incineration contains a certain amount of heavy metal substances such as iron, copper, zinc, chromium, etc., which has recycling value and can be used as a resource for development and utilization. Generally, the thermal ignition loss rate of slag is about 1.4%-3.5%, and the low thermal ignition loss rate reflects its good incineration effect. Untreated incinerator slag is mainly composed of slag, glass, ceramic fragments, iron, and other metals. Among them, large-particle slag (>30mm) is mainly ceramic/brick and iron, and the mass percentage of the two substances decreases with the decrease of particle size; small-particle slag (<30mm) is mainly slag and glass Its content increases with the decrease of the particle size, which is mainly caused by the physical properties of these substances and the impact force experienced when they move in the grate.

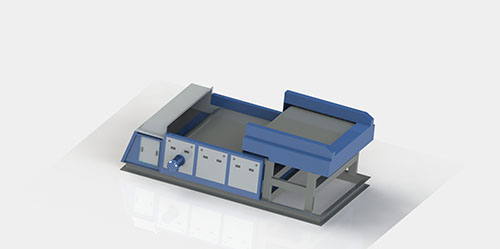

Generally, a dry slag processing system includes a feeding receiving unit, a screening unit, a crushing unit, a transfer unit, a dust removal unit, and so on. This 3D model is a process flow of dry slag treatment.