"Improving The Quality" Is The Top Priority For The Construction Waste Highlighted In The "New Solid Waste Law".

In 2017, the National Development and Reform Commission and other officials jointly issued the Circular Development Leading Action, which set a target for the recycling rate of urban construction waste to reach 13% by 2020. However, despite this, the recycling rate of construction waste in China is far lower than that of the United States (70%), Germany (90%), and Japan (97%).

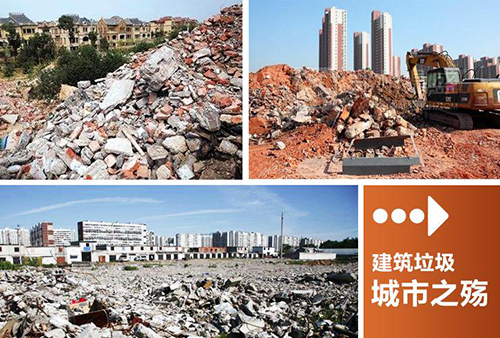

With the acceleration of China's urbanization, hundreds of millions of tons of construction waste will be generated every year. In recent years, national policies related to the recycling of construction waste have emerged frequently, guiding the direction of industrial development. In March 2018, the Ministry of Housing and Urban-Rural Development carried out a pilot project on construction waste management in 35 cities (districts) across the country, comprehensively improving the whole-process management of construction waste, and promoting it nationwide on the basis of the pilot project.

On September 1 last year, the newly revised Law of the People's Republic of China on the Prevention and Control of Environmental Pollution by Solid Waste came into effect, separating construction waste from domestic waste in the solid waste law and treating it as a major category. It is also clear that local people's governments at or above the county level should strengthen the prevention and control of environmental pollution caused by construction waste, establish a classification and treatment system for construction waste, encourage the use of advanced technologies, processes, equipment, and management measures, promote the reduction of construction waste at the source, and establish a recycling and utilization system for construction waste.

According to the source of production, construction waste can be divided into engineering residual waste, demolition waste, construction waste, and decoration waste. Concrete, brick, and lime soil mix types account for 70-80% of the total construction waste. In addition, there are glass, metal, bamboo and wood, paper and the plastic combustible type and so on.

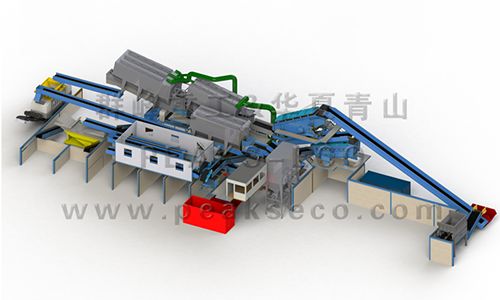

The composition of construction waste is so complex, how to improve its utilization rate of resources and realize a virtuous cycle of construction waste recycling? In response, Qunfeng Heavy Industry & Huaxia Qingshan proposed a unique mixed waste disposal system for construction and demolition. After garbage is sorted, inert ferrous metals and non-ferrous metals are screened out, non-recyclable materials are removed, and all metals that can be recycled and sorted are transported to professional companies for sorting and treatment. Inert materials are recycled and re-marketed to the civil construction market as alternatives to traditional quarry products; Other selected wastes, including asphalt, concrete, and masonry, are recycled into gravel and roadbed materials, as well as clean, wet, and mixed filling materials.

In the process of construction waste treatment, Qunfeng Heavy Industry & Huaxia Qingshan also uses water flotation equipment to accurately remove impurity and further remove non-aggregate impurities in construction waste (for example Plastic, wood, fabric, etc.), the purified high-purity aggregate can be used for brick, paving stone, roadbed water stability layer and other aspects of the construction engineering applications.

The metal separation system uses permanent magnets to separate the iron from the waste without the need for a motor drive. Conveyor belts revolve around huge permanent magnets to separate wire, nails, and gas canisters. The body of the magnetic separator is made of steel structure, non-magnetic, so as to avoid the iron material on the body of the magnetic separator.

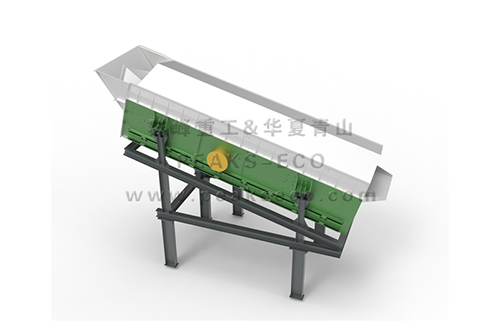

Qunpeak composite screen can be screened twice in one operation, providing a high-efficiency screening solution for viscous, moist materials. It is an ideal choice for compost, wood, garbage, roller screening fine material, construction waste, and incinerator ash.

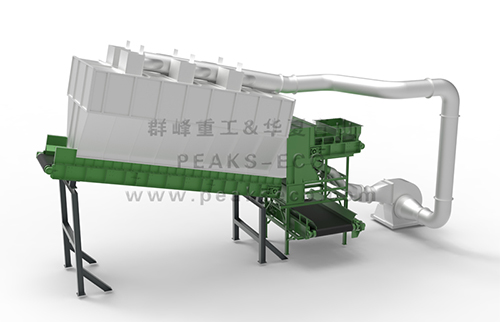

The separation technology of the air separation system makes use of the density characteristic of garbage and uses airflow to separate garbage effectively. This technology can improve the recovery rate of small-volume garbage. The shape and function of the equipment are personalized designed to meet the different needs of customers.

Water flotation material recovery equipment is the use of the water-filled tank, which will be light material and heavy material separation equipment. A conveyor with a brush is used to screen out the light material floating on the surface of the water, while the heavy material sinking to the bottom is collected by the conveyor immersed in the water, and then the two materials are transported and stored separately. Screw conveyors at the bottom of the pool can remove sunk sediment to keep the pool clean.

The mixed waste treatment system of construction and demolition launched by Qunfeng Heavy Industry & Huaxia Qingshan can improve the level of resource utilization, reduction and harmless treatment of construction waste, and truly realize high-quality recycling of construction waste.