An industrial baler machine is generally used for packaging various products into firm, stable and space-saving bales. PEAKS-ECO baler machine such as hydraulic baler machine, paper baler machine, plastic baler machine, metal baler machine can offer a complete range of fully-automatic baler machines for sorting, weighing, compressing, baling and palletizing a great variety of compressible materials. We manufacture high-performance baler machines for organizations in various industries. If you are a paper or plastic recycler, PEAKS-ECO will have a plastic baler machine that will meet your needs. Plus we offer the best baler warranty in the business!

Hydraulic balers are the backbone of many industries due to their versatility and power. These machines are equipped to handle various compressible materials, such as agricultural waste, metal scraps, and textiles. PEAKS-ECO’s Hydraulic Press Straw Baler is particularly suited for agricultural companies, producing bales with a density 33 times higher than the incoming material.

Applications:

Storing forage for livestock during winter.

Producing biomass for alternative energy sources.

Benefits:

Compact bales reduce storage requirements.

Long-term storage capabilities.

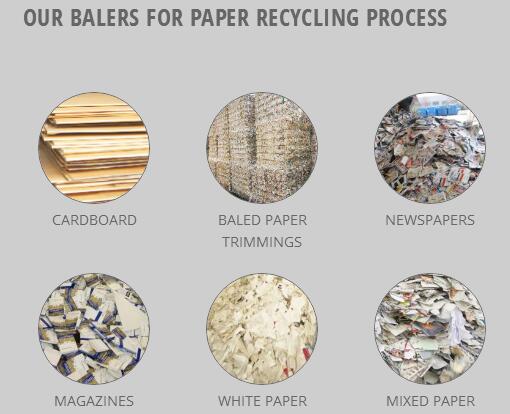

Paper balers fall under the broader category of industrial balers and are indispensable for recycling facilities and waste management companies. These machines efficiently handle paper, cardboard, office paper, and other related materials.

Applications:

Compressing office paper for recycling.

Handling aluminum, plastic packaging, and automotive parts.

Process:

Paper balers apply sufficient pressure to press materials into bales of various sizes and shapes, optimizing storage and transportation.

Plastic waste is one of the most challenging materials to manage. PEAKS-ECO’s plastic balers are specifically designed to process diverse plastic materials, including PET, HDPE, big bags, rigid plastics, and plastic films.

Key Features:

Equipped with bag openers and storage bunkers for sorting plastics by type.

High-density bales optimize transportation costs by reducing free space in trucks and containers.

Benefits:

Increased efficiency in recycling processes.

Cost-effective logistics and storage solutions.

Metal balers are indispensable for recycling facilities that handle ferrous and non-ferrous metals. These machines efficiently compress scrap metals into dense bales, maximizing the value and ease of transportation.

Applications:

Recycling metal scraps from manufacturing industries.

Compacting metal fragments for resale or reuse.

Advantages:

Enhanced safety and cleanliness in waste management.

Economical waste collection and transportation.

Solid waste balers are versatile machines capable of handling small debris, such as textile fabric scraps, metal fragments, and other unsalable materials. These machines are ideal for waste collection, recycling, or sale to secondary markets.

Features:

Economical waste handling.

Suitable for both disposal and recycling operations.

Baler machines have revolutionized waste management and material handling across multiple sectors:

Recycling:

Balers are essential for recycling facilities, enabling efficient segregation, compression, and baling of waste materials. For example, PEAKS-ECO’s plastic balers can easily adapt to a wide variety of plastics, ensuring high recovery rates and reduced landfill waste.

Agriculture:

Hydraulic straw balers provide a sustainable solution for agricultural waste. By compacting straw into dense bales, farmers can reduce storage costs and create valuable biomass for energy production.

Manufacturing:

In the manufacturing industry, metal and paper balers streamline the handling of scrap materials, ensuring they are recycled or reused effectively.

Logistics and Transportation:

High-density bales produced by balers help optimize the use of transportation vehicles, reducing logistics costs and environmental impact.

PEAKS-ECO’s balers come equipped with fully-automatic systems for sorting, weighing, compressing, and baling. This reduces manual labor and speeds up production processes, making them ideal for large-scale operations.

Our machines are designed to consume less energy while maintaining high performance, making them a cost-effective and eco-friendly choice for industries.

Each baler machine can be tailored to meet specific customer needs, from bale size to material type, ensuring maximum flexibility and efficiency.

Unmatched Warranty:

We offer the best baler warranty in the industry, providing our customers with complete peace of mind.

Expert Support:

Our team of experts provides comprehensive support, from machine installation to maintenance and troubleshooting.

Industry Expertise:

With years of experience in manufacturing baler machines, PEAKS-ECO is trusted by companies worldwide to deliver high-performance solutions.

Sustainability Commitment:

By investing in our baler machines, you contribute to a more sustainable future by promoting recycling and reducing waste.

The global baler machine market is expected to grow at a CAGR of 5.8% from 2023 to 2030, driven by increasing demand for waste management solutions.

Recycling rates for materials like paper and plastic have increased significantly, with baler machines playing a crucial role in achieving these figures.

Advances in automation and AI are transforming the baler machine industry, enabling smarter and more efficient waste management.

Peaks Eco is your trusted partner for all kinds of baler machines. Whether you’re looking for a hydraulic baler, plastic baler, or paper baler, we have the solution to meet your needs.

Get in touch with us today to learn more about our products and services. Let PEAKS-ECO help you optimize your waste management processes and achieve your sustainability goals!