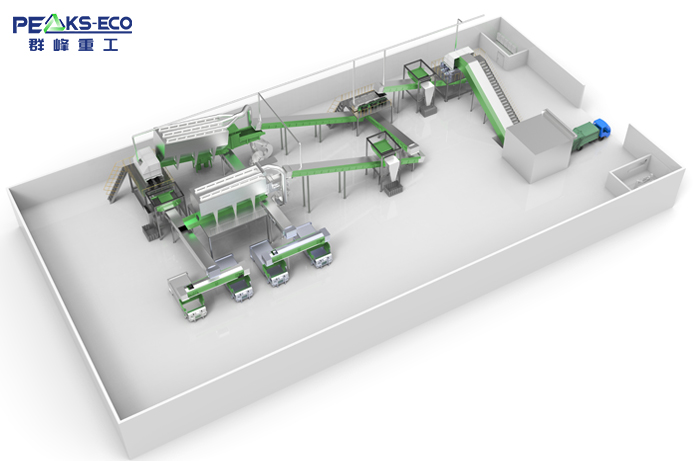

In order to make the maximum use of waste resources, Qunfeng launched a more complex process route, the route on the basis of the original increase in the vibrating screen system, bouncing screen system, AI robot system, can be industrial, commercial waste for fine classification. Through these systems, we can screen out wood, paper, fiber, concrete, brick, metal, etc. The screened material can be transported directly to downstream units for reuse.

Industrial and commercial waste directly into the coarse crusher after special garbage truck comes into play into the hopper, torn bags at the same time the material particle size break below 250 mm, after primary crusher of living garbage by transport belt conveyor to chart screen, residual life garbage to sieve, chart chart screen for oversize living garbage sorting and undersize two specifications. Screening process at the same time with a magnetic separator screen out metal material. The material above and below the screen is transported to the air separator, the heavy material is separated by the air separator, and the heavy material (stone, glass, concrete, etc.) is transferred to the designated place for landfill; Light substances (paper, plastic and other combustible materials) enter the secondary crusher, the waste after secondary crushing is separated from iron (magnetic material) material by iron separator, and the remaining waste is made into finished waste (RDF fuel).

In order to make the maximum use of waste resources, Qunfeng launched a more complex process route, the route on the basis of the original increase of composite screen, bouncing screen, AI robot system, can be industrial and commercial waste for fine classification. Through these systems, we can screen out wood, paper, fiber, concrete, brick, metal, etc. The screened material can be transported directly to downstream units for reuse.