Eddy Current Separator (Non-Ferrous Separator) is to separate non-ferrous metals by the induction principle (eddy current) of a high-frequency magnetic field.

System to Separate Non-Ferrous Metals by High- Frequency Magnetic Field

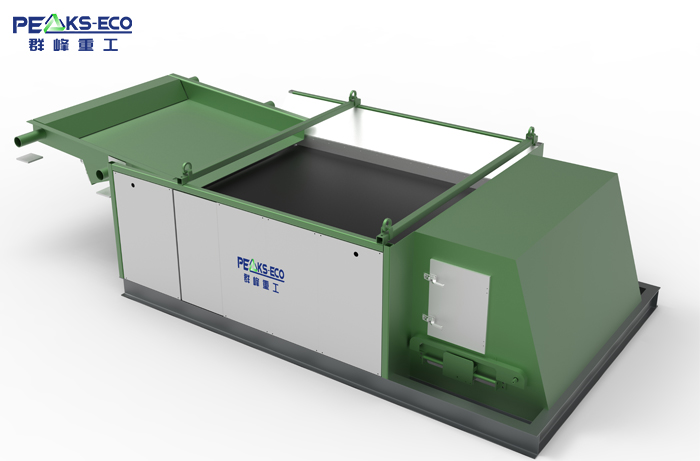

Eddy Current Separator (Non-Ferrous Separator) is to separate non-ferrous metals by the induction principle (eddy current) of a high-frequency magnetic field. The powerful moving magnetic field on the surface of the drum is generated when the powerful permanent magnet inside the drum rotates at high speed, separating three types of materials: iron, non-metal, and nonferrous metals such as aluminum and copper. The permanent magnet drum of high capability rotating inside the conveyor belt at high speed induces the eddy current in non-magnetic nonferrous metals moving on the drum to generate a magnetic field. This force is exerted in the opposite direction to gravity, and nonferrous metals bounce off by repulsive power from mixed wastes during movement on the conveyor belt. Non-Ferrous metals with larger surface areas, lighter weight and higher conductivity are usually well separated. The separator requires virtually no maintenance and guarantees the stable separation for long-term operation. The Non-Ferrous Separator is installed together with a permanent magnetic separator on MSW to play an important role for sorting waste.

Separating nonferrous metals from wastes.

The Eddy Current Separator operates on the principle of electromagnetic induction, which involves the interaction between a magnetic field and a conductor.

Conveyor Belt and Rotor:The material mixture is fed onto a conveyor belt, which moves it towards a rapidly rotating magnetic rotor. The rotor is housed inside a non-metallic drum.

Magnetic Field Generation:The rotor contains a series of powerful permanent magnets arranged in such a way that they generate a strong and changing magnetic field as the rotor spins.

Induced Eddy Currents:When a non-ferrous metal particle passes through this changing magnetic field, it induces swirling electric currents (eddy currents) within the metal particle itself. These eddy currents create their own magnetic field, which opposes the magnetic field of the rotor, causing a repulsive force.

Separation Process:The repulsive force generated by the interaction between the induced eddy currents and the rotor's magnetic field propels the non-ferrous metal particles away from the other materials on the conveyor.The non-ferrous metals are thrown off the end of the conveyor into a separate collection area, while the remaining materials continue to move along the conveyor for further processing.

How does Eddy Current Separator Work?

Eddy Current Separators are used in various industries for the separation of non-ferrous metals, including:

Recycling Industry:

Municipal Solid Waste (MSW) Recycling: Separating aluminum and copper from plastics, glass, and other waste materials.

Scrap Metal Recycling: Recovering valuable non-ferrous metals from shredded vehicles, appliances, and electronic waste (e-waste).

Mining Industry:

Ore Processing: Separating valuable non-ferrous metals from mined ores.

Glass Recycling:

Cullet Purification: Removing metal contaminants from recycled glass cullet.