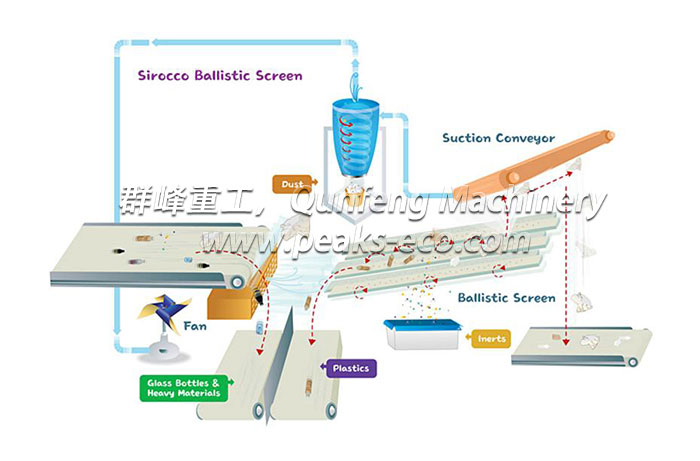

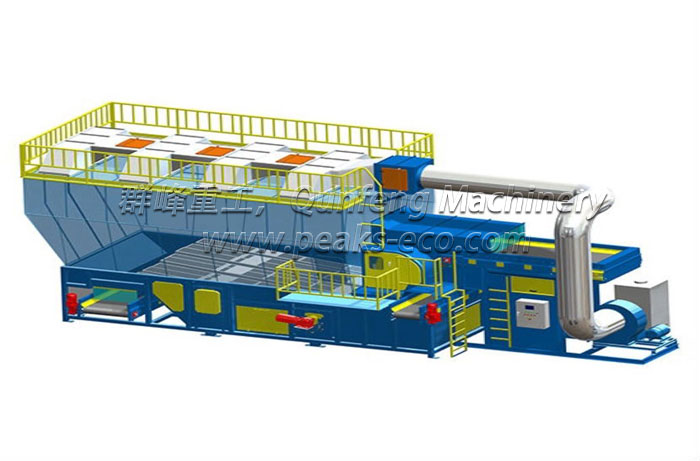

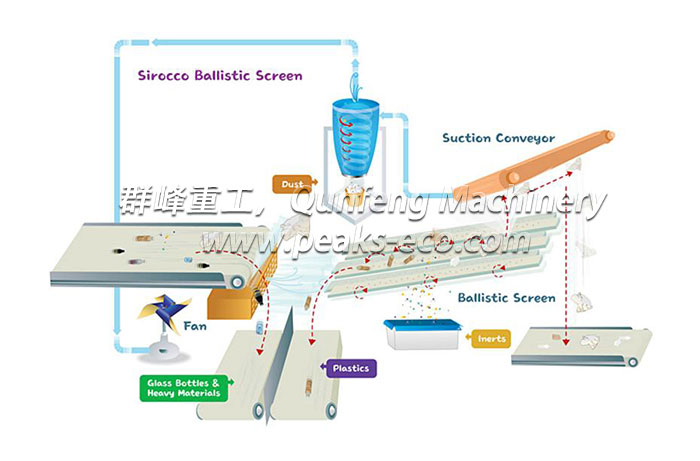

Combination of Air separator and Ballistic Separator. Air & Ballistic separator is a hybrid screen with the advantages of the Air separator and the Ballistic Screen.

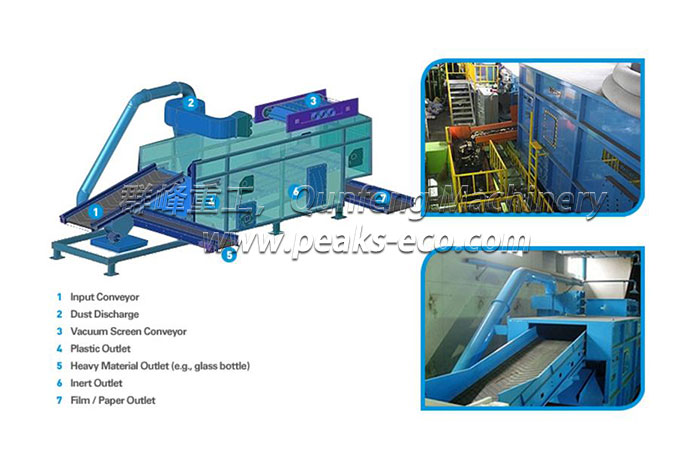

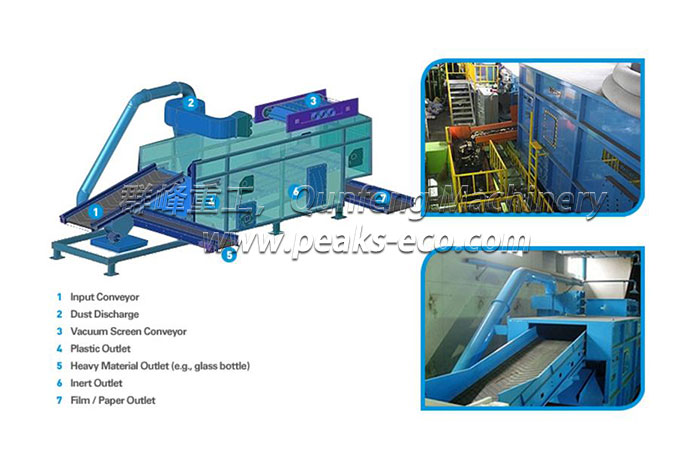

Air & ballistic screen is to separate the plastic materials with shapes (3D) from the paper and film materials (2D) depending on the paddle design after sorting out glass bottles, and frequently used at MSW. Wastes stream fed by the conveyor are processed as follows: heavy weight materials are first separated by the air shifting, and light weight materials are put into the ballistic screen, the materials with 3D shape (e.g., PET bottle and milk bottle) are bounced and moving down to the lower part of the paddles by the low gradability. On the other hand, paper and film materials with 2D shape are separated by climbing up the paddles at different speeds according to their gradability. Dust blown by the wind of the blower during the air shifting are absorbed by the vacuum screen conveyor mounted on the ceiling of the ballistic screen and collected by the cyclone.

Small size impurities are discharged below the screen through the holes of the ballistic paddles. The air polluted during waste separation is absorbed and purified by a cyclone system, and dusts are separately discharged to perform air purification function, which helps improve the environment of the work site and reduce air pollution.

Air & Ballistic separator is installed on the subsequent process of the bag splitter to separate the waste stream to five categories such as 1) glass bottle, and PET bottles containing water, 2) plastic containers, 3) paper and film, 4) inert and 5) dusts to maximize efficiency of the recyclable sorting line.

Characteristics and Advantages:

1. Excellent separation capability by gradability

2. Preventing airborne dusts by air-circulation design

3. Improving the efficiency of subsequent processes

4. Separating inert by ballistic paddle hole design

5. Sorting Five Categories

6. In creasing throughout by 50% compared to common ballistic screen

Application

1. Separating combustible waste, recyclables and landfill waste

2. Separating glass bottles, chinaware and heavy steel can

3. Separating plastic containers

4. Separating film and paper

5. Separating inert

6. Separating Dusts smaller than 10mm

7. Pre-treatment for MSW

8. Replacement for normal Ballistics and Air Shifter