The most popular of the Peaks-eco Auto Tie Baler Machine operating in Asian and Europe. The 850 series has an extensive range of designs and configurations. The different models produce bales of between 400 and 800kg, with varying output options to suit actual requirements.

The Peaks eco FDY 850 series of semi and fully automatic horizontal balers are popular across many industries and can deliver outstanding results for your business.

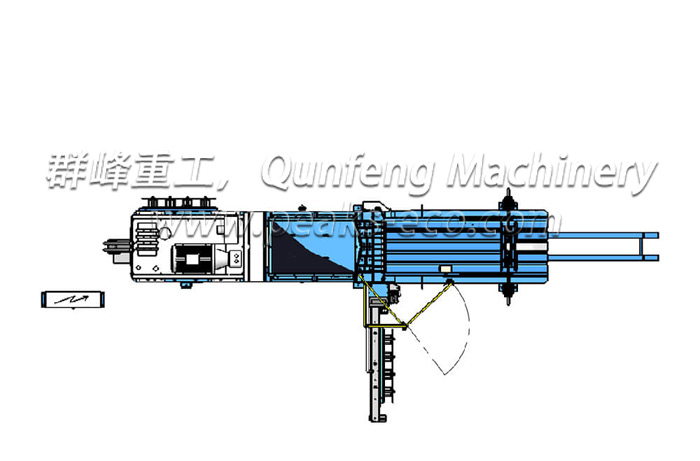

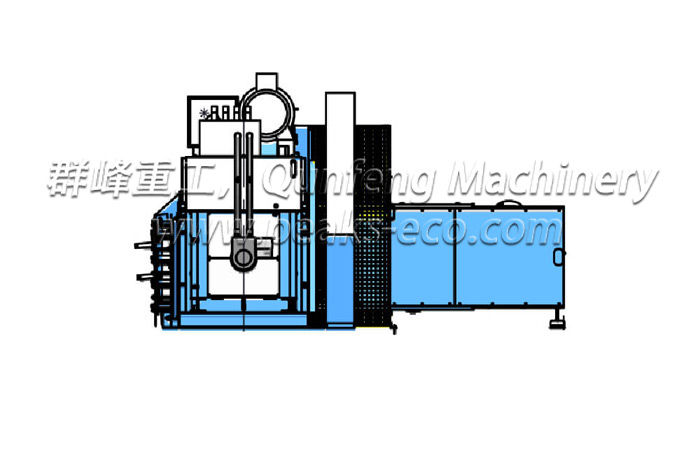

The automatic operation of these balers substantially reduces required labour for processing of materials and with the vertical wire tie setup, keeps the footprint compact enabling you to install the baler in many tight locations and in close proximity to the where the material is generated inside your facility, which creates great opportunities for reducing time and handling of moving materials through your facility.

The loading setup options are endless and include all the regular loading options including: hand-load, hydraulic bin lifter, conveyor, air conveyor, mobile equipment as common examples. In addition, we are able to offer both the space saving vertical wire tying option, as well as the traditional horizontal wire the option, which provide opportunities to process just about any product in just about any environment.

A great investment for your business, offering financial, operational and environmental benefits for your business, in operation in Asian and Europe. A few more examples are as follows:

A great investment for your business, offering financial, operational and environmental benefits for your business, in operation in Asian and Europe. A few more examples are as follows:

Automatic operation

Space saving vertical wire tie system

Horizontal wire tie system

Large hopper and opening

Variable bale length to suit your requirements

High compaction force producing a dense bale

Easy to use controls,

Easy access for wire replacement

Easily processes a range of materials, including: cardboard, paper, trim, paper offcuts, plastic film and beverage containers

Suits a range of different Industries, including: Industry, Manufacturing, Print, Packaging, Retail, Logistics, Distribution, Recycling, Materials Recovery Facilities (MRF’s)

Ideal for processing recyclable volumes and fed continuously by either: hand, bin lifter, conveyor or air conveying and separation systems, mobile equipment or a potential combination of these solutions.

Parameters of 850 B full-automatic waste paper baler machine | ||||||

1 | Main cylinder | Mode | Φ220 | Travel | 2600mm | Homemade cylinder |

Nominal force | 930KN | Amount | 1 set | |||

2 | Side plate of main cylinder | 10# | ||||

3 | Pressure of hydraulic system | 1500KN | ||||

4 | Feed Opening size | 1100*2000mm | ||||

5 | Bale size | 1100*850*L(Adjustable:1500-2000) | 3 lines | |||

6 | Bale density | 500kg/m³ | ||||

7 | Main engine power | 30KW+5.5KW+5.5KW | ||||

8 | Power supply specification | 25m² soft copper | ||||

9 | Packaging line | 12# iron wire | ||||

10 | Operation Way |

Manual operation / Automatic | ||||

11 | Cooler | 8m² | ||||

12 | Production capacity | 7-10 bales per hour | ||||

13 | Hydraulic pump mode | Plunger pump 160ml/r*1 Gear pump 25ml/r*1 | FWD | |||

14 | Capacity of Fuel tank | 1.5m³ | ||||

15 | Conveyor (Steel tank Structure) | W2*9 m | ||||

16 | Dimension of main engine | 8000*4000*3200 mm | ||||

Advantages Of The Baler Machine